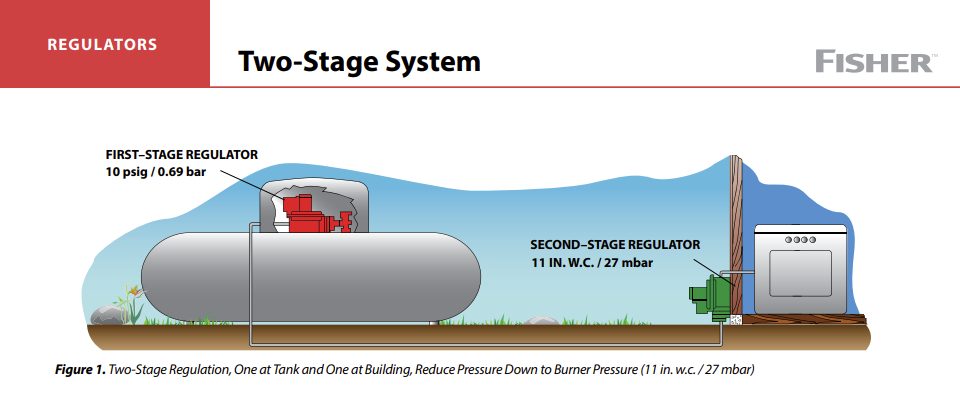

A Two-Stage Regulator System is defined in NFPA 58 as, “An LP-Gas vapor delivery system that combines a first-stage regulator and a second-stage regulator(s), or utilizes a separate integral two-stage regulator.” In section 6.10.2, the requirements for this type of system are covered. In short, a two-stage system or 2-psi regulator system is required on all fixed piping systems and mobile food facilities that serve 1/2 psig appliance systems. Single-stage regulators on fixed piping systems have not been legal since June 30,1977. The only exception for single-stage regulator use is on small portable appliances and outdoor cooking appliances with input ratings of 100,000 btu/hr or less. If you work on a system that has a single-stage regulator installed, then you must upgrade this system to a two-stage system.

A Two-Stage Regulator System is defined in NFPA 58 as, “An LP-Gas vapor delivery system that combines a first-stage regulator and a second-stage regulator(s), or utilizes a separate integral two-stage regulator.” In section 6.10.2, the requirements for this type of system are covered. In short, a two-stage system or 2-psi regulator system is required on all fixed piping systems and mobile food facilities that serve 1/2 psig appliance systems. Single-stage regulators on fixed piping systems have not been legal since June 30,1977. The only exception for single-stage regulator use is on small portable appliances and outdoor cooking appliances with input ratings of 100,000 btu/hr or less. If you work on a system that has a single-stage regulator installed, then you must upgrade this system to a two-stage system.

Why is this important? The following information helps to answer this and is pulled from the Fisher LP-31 Education & Guidance section.

There are advantages to a two-stage system. First, let’s look at safety. The internal relief valve on a single or second-stage regulator can provide adequate over-pressure protection for a malfunctioning regulator that may, for example, not lockup due to a worn disc or debris stuck on the valve disc. However, only a large capacity relief valve in a second-stage regulator can limit downstream pressure to psig to the appliance if there is a mechanical failure in the regulator. Such performance is accomplished because the first-stage is presumed to be operational and still providing 10 psi to the second-stage regulator. Thus, the second-stage relief valve does not have to be sized for the full 250 psi tank pressure. This important feature will stop excess gas being put into a building during an over-pressure situation and can prevent an incident.

Another advantage to a two-stage system is pressure consistency. When you have a single-stage regulator trying to take in anywhere from 10 - 250 psi inlet pressure and knock it down to 11” WC, you’re going to have varying output because of that wide variance on inlet pressure. If you have a first-stage or integral regulator installed, the system will go through two knockdowns which will make the pressure a lot more constant on the second-stage portion. With a constant 10psi inlet, this regulator can maintain a constant 11” WC outlet pressure to your appliance which will result in more consistent operation for your end-user.

Something else that you may not think of right away when utilizing a two-stage system is that this will reduce the amount of regulator freeze ups! There are a few reasons for this. 1.) A larger orifice can be used in the second stage regulator which results in a lower chance that ice can fully block it. 2.) Because pressure reduction occurs at both the first and second-stage regulators, it creates less cooling and more heat transfer into each regulator, lowering the chance of freezing. And, 3.) Most second-stage regulators are mounted on the side of a wall with the inlet piping coming up out of the ground. This orientation allows any condensed moisture to drain away from the orifice, the coolest part of the regulator during pressure reduction. With minimal pressure drop at the second-stage orifice and moisture draining away from the large second-stage orifice, it becomes more difficult for water to freeze in the second-stage regulator.

Speaking of cool, I hope you are enjoying the greater demand of the cooler weather. Let’s hope it sticks around awhile and makes for a profitable heating season! I hope you found this information helpful, stay safe out there.

Email Darren: Dmcardle@gardnermarsh.com

Product Spotlight

Construction can’t slow down because of cold weather! It is often imperative to keep new construction warm. Higher temperatures help professionals stay warm while working, allows paint and stain to dry quicker, helps concrete and drywall mud to cure quickly, etc. We offer several options for temp heat. From forced air heaters to high-btu ducted portable heaters, we have you covered! We also offer all the hosing in various sizes to keep these units running. Temp heat can be a real revenue generator and gallon producer if you can keep up with the fill ups on top of your normal customers. When I was in operations, we scaled up big time for temp heat jobs. I had close to 100 heaters always on the ready to deploy at the beginning of the season and often sold more than 100k gallons in a short amount of time! Not only is it great short-term business, it also allows you to build relationships with local contractors and capture additional business like tank sets, piping, and appliance sales! Check out many of our options here.

Construction can’t slow down because of cold weather! It is often imperative to keep new construction warm. Higher temperatures help professionals stay warm while working, allows paint and stain to dry quicker, helps concrete and drywall mud to cure quickly, etc. We offer several options for temp heat. From forced air heaters to high-btu ducted portable heaters, we have you covered! We also offer all the hosing in various sizes to keep these units running. Temp heat can be a real revenue generator and gallon producer if you can keep up with the fill ups on top of your normal customers. When I was in operations, we scaled up big time for temp heat jobs. I had close to 100 heaters always on the ready to deploy at the beginning of the season and often sold more than 100k gallons in a short amount of time! Not only is it great short-term business, it also allows you to build relationships with local contractors and capture additional business like tank sets, piping, and appliance sales! Check out many of our options here.