Gardner Marsh News

-

February 02, 2026

If you know much about me, you know I have 4 daughters. Having 4 kids, it’s very apparent I LOVE dad jokes. It might be annoying to some, but it cracks me up. So this month let’s see if we can connect the dots on the various options for residential appliance connectors! See what I did there? Classic.

You have several options when choosing what to use for connectors. We are a stocking distributor of Dormont Gas Connectors, so lets cover their lines.

On the residential side, we offer five different lines to choose from, all with their own applications, features, and benefits. The options include standard uncoated stainless steel, yellow-coated stainless steel, high-temp black powder coated, high-btu high-temp black powder coated, and gray-coated high btu stainless steel.

The uncoated stainless steel is the base offering. These are durable, naturally corrosion resistant 304 stainless

-

January 01, 2026

I bet you’re getting lots of calls for gas log service and installation right now! We’ve been getting quite a few people asking about the differences between Millivolt & IPI burners, so this month That’s what we’re going to review.

Helping your customer choose the right ignition system for their log set can significantly affect convenience, efficiency, and long-term operation. The two most common systems we sell are Millivolt (Standing Pilot) and IPI (Intermittent Pilot Ignition). While both are reliable, they function very differently and each have their own benefits. I don’t have room to cover Variable flame burners in this newsletter today, but that is another commonly used standing pilot system.

Let’s start with Millivolt systems. These burners use a continuously burning pilot flame. This small flame generates a tiny electrical current (millivolts) that powers the gas valve and allows the burner to come on.

-

December 08, 2025

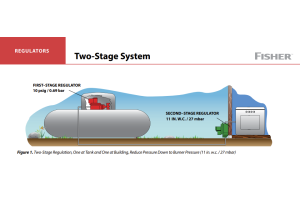

A Two-Stage Regulator System is defined in NFPA 58 as, “An LP-Gas vapor delivery system that combines a first-stage regulator and a second-stage regulator(s), or utilizes a separate integral two-stage regulator.” In section 6.10.2, the requirements for this type of system are covered. In short, a two-stage system or 2-psi regulator system is required on all fixed piping systems and mobile food facilities that serve 1/2 psig appliance systems. Single-stage regulators on fixed piping systems have not been legal since June 30,1977. The only exception for single-stage regulator use is on small portable appliances and outdoor cooking appliances with input ratings of 100,000 btu/hr or less. If you work on a system that has a single-stage regulator installed, then you must upgrade this system to a two-stage system.

Why is this important? The following information helps to answer this and is pulled from the Fisher LP-31 Education & Guidance section.

-

November 03, 2025

We sell a lot of Rinnai tankless water heaters, I am talking pallets of these everyday! When customers call in though, they sometimes aren’t sure which model they are looking for. One of the questions we typically ask is, “Do you want a non-condensing or condensing model?” The most common response is, “What’s the difference?”

Let’s explore the answer to this question. Everyone is different, but if you ask me what the difference is, I am going to start with efficiency. If your customer wants to be green, then I push towards condensing. If your customer doesn’t care, then I am going to ask you where the heater will be located and how much venting you will need to install. If you tell me it is in the middle of the house and you need to run a bunch of venting, and you are able to find a place to drain the condensation, I will again push towards condensing.. If the unit is outside or you only have a short venting run, then

-

October 02, 2025

Drip legs versus sediment traps, what’s the difference? Many often refer to these interchangeably and while their design can be exactly the same, it is their purpose that varies. In short, a drip leg catches liquids, while a sediment trap catches debris. The easiest way to remember this is to associate drip with wet and sediment with debris.

Drip Leg

NFPA 54 3.3.31 calls a drip leg just a drip and it is defined as “the container placed at a low point in a system of piping to collect condensate and from which it may be removed.” Further in the code book, 7.6.2, it is outlined that they shall be installed only in such locations that they are readily accessible to permit cleaning or emptying. They should not be located where the condensate is likely to freeze. There are no design parameters/requirements listed in the code book.

Sediment Trap

-

September 03, 2025

Here we go y’all! It’s about time to start ramping up business and hoping for cooler weather. I am probably a little late with this newsletter, but if you haven’t already been getting the pilot light calls yet, they are coming! My question to you is: do you wait for these calls to come in every year, or are you proactive about getting ahead of it? Do you offer any type of maintenance service or plan to keep you busy over the summer?

I highly suggest you consider offering service plans on appliances. We are always looking for ways to stay busy and make money through the summer months. Why not offer a service customers must utilize from April to September? Develop a calling/scheduling program that begins in March to capture this business.

Most appliances require maintenance of some variety you can turn into a package. The way to make it successful is to market it the correct way to the correct audience and -

August 01, 2025

This month brings good news for all you Fisher folks out there! This could also be exciting news for those who are on the fence about trying Fisher; maybe this will be the catalyst for you to give them a shot.

Fisher has been providing top quality equipment since 1880 and they have always stood behind their product. They are putting a stronger stamp on that commitment by updating their Manufacturer’s warranty from 5-years to 10-years. This warranty change is effective as of July 1, 2025 and is across their entire Fisher LPG Equipment product portfolio.

According to David Schmidt, Fisher’s Sales Director for North America, “This enhancement further demonstrates our commitment to quality and reinforces the trust our customers have in our brand. By offering a 10-year Manufacturer’s Warranty, we are reaffirming our dedication to excellence and customer satisfaction.”

Fisher

-

July 01, 2025

Hopefully after last month’s newsletter you thought about your process regarding pressure testing new systems. This month we are moving into Leak Testing. Again, any code references will be from the 2024 versions of NFPA 54/58.

When are leak tests required? The official NFPA code in both 54 (8.2.3) & 58 (6.18.2) states, “Immediately after the gas is turned on into a new system or into a system that has been initially restored after an interruption of service, the piping system shall be checked for leakage.” I’ve heard several arguments about what qualifies as an “Interruption of Service”. The official NFPA definition for that in NFPA 54 - 3.3.61 defines an Interruption of Service as a, “disconnection or discontinuation of fuel gas to the point of delivery.” Some examples would be an out of gas situation or a tank that was disconnected due to non-payment or some other reason.

-

June 02, 2025

Let’s talk inspection and testing of gas piping! Any code references I make are from the 2024 versions of NFPA 54/58; please check your state’s adopted version for current requirements in your area.

It should be common sense in our line of work that all installations, regardless of the installer, should be inspected and tested prior to putting them into service and taking on the liability of supplying a flammable vapor to your customer. But common sense can sometimes escape us, especially when returning to our own installation. I have heard many stories from Service Technicians who have put gas to a system just to either immediately hear the woosh of an open line or watch their pressure gauge hit zero immediately. It is important to inspect the installation prior to making it live.

Some key things to look for when doing a system inspection:

1.) Do all materials comply with required codes? i.e. no garden hoses, no copper fittings in concealed locations, etc

-

May 01, 2025

I’m sure you are aware of the local 811 services in your area, but did you know your state has laws pertaining to line locating, and they can vary state-to-state? You can find out what is required in your state by visiting the national 811 site, call811.com. Simply click on the “811 in Your State” link and select your state. You can then submit a locating request or visit your state’s 811 site.

For the purpose of this newsletter, I’m going to point out some common North Carolina FAQs as they pertain to the 811 process.

If you intend to excavate your customer’s yard for the purpose of buried gas lines or a buried propane tank, then you will need to notify 811 at least 3 days prior to your service appointment. You can track your request on the nc811.org website to make sure it has been completed. I would highly recommend that you mark your intended excavation in white paint or flags. You will also want to notify your customer that they are responsible