Hopefully after last month’s newsletter you thought about your process regarding pressure testing new systems. This month we are moving into Leak Testing. Again, any code references will be from the 2024 versions of NFPA 54/58.

Hopefully after last month’s newsletter you thought about your process regarding pressure testing new systems. This month we are moving into Leak Testing. Again, any code references will be from the 2024 versions of NFPA 54/58.

When are leak tests required? The official NFPA code in both 54 (8.2.3) & 58 (6.18.2) states, “Immediately after the gas is turned on into a new system or into a system that has been initially restored after an interruption of service, the piping system shall be checked for leakage.” I’ve heard several arguments about what qualifies as an “Interruption of Service”. The official NFPA definition for that in NFPA 54 - 3.3.61 defines an Interruption of Service as a, “disconnection or discontinuation of fuel gas to the point of delivery.” Some examples would be an out of gas situation or a tank that was disconnected due to non-payment or some other reason.

I am not going to get into all of the specifics of what a leak test is, but here are some highlights. All of these are found in NFPA54—Annex C. As well, Annex C.3(2) lists 5 methods of performing a leak test.

- All leak tests must hold for a minimum of 3 minutes with no signs of leakage

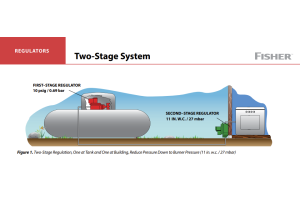

- If performing the test between the tank and the 1st-stage/integral regulator—the pressure must be dropped a minimum of 10psi from the initial reading prior to starting the test time

- If performing the test after the 1st-stage, but prior to the 2nd-stage regulator using a 30# gauge, pressure must be dropped by a minimum of 2psi to allow the 1-stage regulator to unlock

- If performing the test after the 2nd-stage regulator using inches of water column, you must preform the test at 9” WC +/- 1/2” to ensure all regulators are unlocked and that a leak anywhere in the system is communicated to the gauging device

- If a leak is detected, then the system must be inspected to determine the cause and once repaired, another leak test must be conducted until it passes

Your company should have leak test procedures published in their Policy Manual and those policies should be followed at all times. There is no acceptable level for leakage, no matter the circumstances, since any amount of leakage can result in a dangerous situation. This is one of the most, if not the most, important procedure you should follow during the installation process. Your documentation on this should be clear and accurate on your work order. Think about if it were to show up in court, you would not want any questions about the numbers you listed or be found liable for not performing a leak test properly. You and your customer’s safety is of the upmost importance so this should be taken extremely seriously.

I hope that the last two months newsletters have shined a little light on these important steps in your daily work and reminded you to take proper care when performing and documenting these tests! Stay safe out there.

Product Spotlight

As discussed last month, pressure testing your new piping is not only integral to the installation process, it is also required by code. The MEJ610/30 pressure test adapter features a 0-30 psi gauge, 3/4” FNPT threads, and a factory installed valve stem for adding air into the system for testing. This test must be performed at a minimum of 1.5 times operating pressure and hold for a minimum of 10 minutes. These are often left behind for AHJ inspections as well.

As discussed last month, pressure testing your new piping is not only integral to the installation process, it is also required by code. The MEJ610/30 pressure test adapter features a 0-30 psi gauge, 3/4” FNPT threads, and a factory installed valve stem for adding air into the system for testing. This test must be performed at a minimum of 1.5 times operating pressure and hold for a minimum of 10 minutes. These are often left behind for AHJ inspections as well.