Let’s talk inspection and testing of gas piping! Any code references I make are from the 2024 versions of NFPA 54/58; please check your state’s adopted version for current requirements in your area.

Let’s talk inspection and testing of gas piping! Any code references I make are from the 2024 versions of NFPA 54/58; please check your state’s adopted version for current requirements in your area.

It should be common sense in our line of work that all installations, regardless of the installer, should be inspected and tested prior to putting them into service and taking on the liability of supplying a flammable vapor to your customer. But common sense can sometimes escape us, especially when returning to our own installation. I have heard many stories from Service Technicians who have put gas to a system just to either immediately hear the woosh of an open line or watch their pressure gauge hit zero immediately. It is important to inspect the installation prior to making it live.

Some key things to look for when doing a system inspection:

1.) Do all materials comply with required codes? i.e. no garden hoses, no copper fittings in concealed locations, etc

2.) Are there any open lines that need to be plugged? This is common for Move Out / Move In customers. Sometimes movers disconnect an appliance such as a dryer or grill and do not properly plug the line.

3.) Are all accessories properly installed? Sediment traps, shut off valves, test ports, etc

4.) Are penetrations properly sleeved and protected?

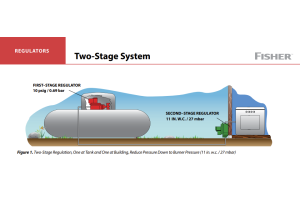

5.) Are proper regulators installed? I have seen many installations where a “professional” has installed a 2nd stage right at the tank or only a high pressure regulator with no 2nd stage at all.

6.) Is there propane in the tank? Lol, seen this way too many times!

These are just a few of the things to look for during an inspection, but they are often overlooked.

Once you have completed your inspection and know what appliances are on gas, you may be ready to test the system. If this is a new installation and you have just installed the piping, you are required to perform a Pressure Test. According to NFPA 54—Chapter 8, you will need to comply with the following:

8.1.2—”The test medium shall be air, nitrogen, carbon dioxide, or an inert gas. Oxygen shall not be used as a test medium”

8.1.4.1—“Test pressure shall be measured with a manometer or with a pressure measuring device designed and calibrated to read, record, or indicate a pressure loss due to leakage during the pressure test period.”

8.1.4.2—”The test pressure to be used shall be no less than 1 1/2 times the proposed maximum working pressure, but not less than 3 psi.”

8.1.4.3—”...a system in a single-family dwelling, the test duration shall be a minimum of 10 minutes. The duration of the test shall not be required to exceed 24 hours.”

8.1.5.1—”The piping system shall withstand the test pressure specified without showing any evidence of leakage or other defects. Any reduction of test pressures as indicated by pressure gauges shall be deemed to indicate the presence of a leak unless such reduction can be readily attributed to some other cause.”

8.1.5.2—”The leakage shall be located by means of a listed combustible gas detector, a noncorrosive leak detection fluid, or other approved leak detection methods.”

8.1.5.3—”Where leakage or other defects are located, the affected portion of the piping system shall be repaired or replaced and retested.”

I believe most of the above to be common sense, however, it’s easy to fall into routine and not pay the codebooks much attention. We all need a reminder sometimes to review the basics and throw a little light on certain areas. This is a good start to a testing conversation. I will continue a review next month with Leak testing. Let me know if you have any questions and stay safe!

EMAIL DARREN: DMCARDLE@GARDNERMARSH.COM

PRODUCT SPOTLIGHT

ME-QTG127A and ME-QTG128B Dual Gauge Kits are used for leak check tests at intermediate pressure using the 30 PSI gauge and also leak check tests at tank pressure using the 300 PSI gauge and the high-pressure test block supplied with the kit. The hose assembly connection to the system pressure tap valve incorporates a quick disconnect fitting to either pressure gauge. Kit includes six pressure tap valves, either type A or type B depending on which kit is specified.

ME-QTG16B Dual Gauge Kits are used for leak check test at intermediate pressure using the 30 PSI gauge and testing first stage regulator. The 35” water column gauge is used for testing low pressure second stage regulator set point and lock up pressure.

ME-SQTG4A and ME-SQTG4B Four Gauge Kits include a 30 PSI gauge, a 300 PSI gauge, a 5 PSI gauge, a 35” water column gauge, and a high pressure test block plus six pressure tap valves either type A or type B depending on which kit is specified. The hose quick  disconnect allows for attachment of any one of the gauges. A leak check pressure tap valve an be anywhere in the system with the proper gauge attached for leak check testing. This kit also allows the service technician to test all pressure regulators, including the first stage, using the 30 PSI gauge, a 2 PSI regulator, using the 5 Psi gauge, and a low pressure 11” W.C. regulators or appliance manifold pressure using the 35” W.C. gauge.

disconnect allows for attachment of any one of the gauges. A leak check pressure tap valve an be anywhere in the system with the proper gauge attached for leak check testing. This kit also allows the service technician to test all pressure regulators, including the first stage, using the 30 PSI gauge, a 2 PSI regulator, using the 5 Psi gauge, and a low pressure 11” W.C. regulators or appliance manifold pressure using the 35” W.C. gauge.

| Part Number | Description |

|

Dual gauge Leak Check Kit – 30 and 300 PSI Gauges with Type B Valves (6) |

|

|

ME-QTG16A |

Dual Gauge Leak Check Kit – 30 PSI and 35” WC Gauges with Type A Valves (6) |

|

Dual Gauge Leak Check Kit – 30 PSI and 35” WC Gauges with Type B Valves (6) |

|

|

Four Gauge Kits (Includes 5,30,300 PSI and 35” WC Gauges) with Type A Valves (6) |

|

|

Four Gauge Kits (Includes 5,30,300 PSI and 35” WC Gauges) with Type B Valves (6) |

IN LINE LEAK TEST ASSEMBLIES

- Reliable method to test high or low pressure tap installations.

- No tools required by driver for leak test. Provides an effective method to bleed pressure for service valve leak test.

- Allows easy method to bleed test vapor from assembly prior to disconnect.

| Part Number | MFG | Description |

| GM |

Container Pressure Leak Test Kit: 300 PSI Gauge Assembly for in line tests with vent valve ME-HSB, 18” Flexible Hose for underground access. For tank pressure “Leak test” |

|

| GM |

10 PSI Leak Test Kit: 15 PSI Gauge Assembly for in line test with vent valve ME-HSB, 18” Flexible Hose for underground access. For 10 PSI “Leak Test” |

PT300 HIGH PRESSURE TEST SET

- High-Pressure test gauge set

- Flexible hose ends for hard-to-reach valves

- Shutoff valve to isolate tank valve

- Bleed port to reduce pressure

- Convenient storage box