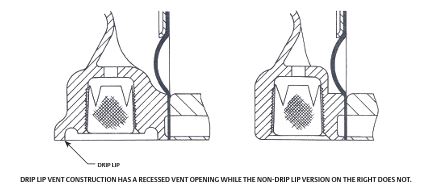

Now that we are in the freeze of winter, let’s talk regulator freeze ups. One of the primary causes of regulator freeze ups is a blocked vent. Many people think the vent is only for relief, but that isn’t accurate. In order to operate correctly, a regulator needs to be able to breathe. Think of the vent as the regulator’s nose. It uses atmospheric pressure in its normal operation, which is what actually allows the diaphragm to flex.

Now that we are in the freeze of winter, let’s talk regulator freeze ups. One of the primary causes of regulator freeze ups is a blocked vent. Many people think the vent is only for relief, but that isn’t accurate. In order to operate correctly, a regulator needs to be able to breathe. Think of the vent as the regulator’s nose. It uses atmospheric pressure in its normal operation, which is what actually allows the diaphragm to flex.

One of the biggest culprits of a blocked vent is freezing rain, snow, and ice accumulation. Of course, all three of these events occur when you are at your busiest. Some of these calls could be prevented with proper installation. It is imperative that the regulator is either protected from the elements or always installed with the vent pointing downward.

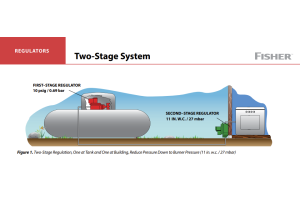

For your first stage or two-stage integral regulator, you will typically have a protective hood or tank dome to protect the regulator. Even so, it is still important to: 1.) still slope the regulator with the vent point downward, even if only at a slight angle; 2.) install your pigtail in such a way that it slopes back towards the tank. Following these two steps will keep water from pooling at the vent and will help keep moisture from inside the tank from reaching the regulator. Where there is not a protective hood or dome, you can install an auxiliary vent assembly to get the results you need.

On the second stage, you must either install the regulator so the vent is pointing straight down or install an auxiliary vent assembly to do so. Even when the regulator is vented away, it still must terminate pointed at the ground.

I highly suggest you review the “Education & Guidance” section in the back of your Fisher LP-31 catalog or on the Fisher App. There is great info in there on this subject and many others that can help you prevent un-needed call outs and provide guidance on proper maintenance and save you and your customer money in the long run.

Product Spotlight

Do you offer temp heat fuel deliveries? If so, have you ever considered a full-service temp heat program? It is a high-demand, fast-paced program, but is also highly rewarding and profitable. I used to have a program we ran every winter renting out these LB White Workman 225 units and hoses. We charged a seasonal rental equal to the purchase price of the heater and rented hose by the foot. We also charged labor for installation and break down plus made great margins on the gas delivery. I had about 75 heaters we rented out to local contractors every year. It is high-demand though, when they called, it was either me or my Operations Manager who took care of them or moved our schedules around to get the appropriate personnel on site. This heater is adjustable from 45,000—225,000 btus, puts out heat in all directions, and comes with a hose, regulator, and QCC connection. You can remove this to install longer hoses if running off of a bulk tank. It is a great unit for this application.

Email Darren: dmcardle@gardnermarsh.com