I will be the first to admit, I used to pass right on by my stash of PPE anytime I was visiting a job or delivering propane. I was a person who always thought it was like winning the lottery, it’ll never happen to me. You’d think I would know better. I had a co-worker get liquid burned on his chest so badly he ended up with a staph infection. Another who was unhooking his delivery hose from an underground tank when the relief valve popped off, blowing liquid into his face and throwing him backwards onto his rear end, leaving him disoriented to the point it took a few minutes for him to realize what happened and remember where he was. We all think that it will never happen, until it does. Luckily, I have never been injured on the job aside from some liquid burns on my fingers, but I have seen and heard enough to know we should be doing everything we can to prevent these accidents from occurring in the first place. As a manager, I should have been setting a better example to the ones I was responsible for. That was poor leadership on my part.

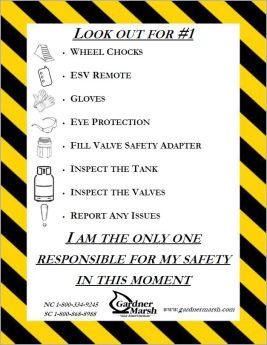

One of the easiest steps we can take is to wear the proper PPE for the job we are performing. What is Personal Protective Equipment (PPE)? It is defined by OSHA as equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and/or illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. It may include items such as shoes, coveralls, body suits,respirators, gloves, safety glasses, ear plugs, hard hats, vests, or other items. Anybody reading this newsletter should be provided with proper PPE by their employer for the job that they are being asked to do. The PPE should be designed and constructed for that job. They should also be providing the training on correct use of the provided PPE, including when and how to use it. It is your responsibility to keep that equipment cleaned, maintained, and to report any issues so that it can be repaired or replaced when necessary. Your company should also have a documented PPE program or policy which addresses the hazards present, proper selection, maintenance, and use of PPE. Having this program is important, as it protects both the company, and more importantly, YOU from being injured and unable to work.

One of the easiest steps we can take is to wear the proper PPE for the job we are performing. What is Personal Protective Equipment (PPE)? It is defined by OSHA as equipment worn to minimize exposure to hazards that cause serious workplace injuries and illnesses. These injuries and/or illnesses may result from contact with chemical, radiological, physical, electrical, mechanical, or other workplace hazards. It may include items such as shoes, coveralls, body suits,respirators, gloves, safety glasses, ear plugs, hard hats, vests, or other items. Anybody reading this newsletter should be provided with proper PPE by their employer for the job that they are being asked to do. The PPE should be designed and constructed for that job. They should also be providing the training on correct use of the provided PPE, including when and how to use it. It is your responsibility to keep that equipment cleaned, maintained, and to report any issues so that it can be repaired or replaced when necessary. Your company should also have a documented PPE program or policy which addresses the hazards present, proper selection, maintenance, and use of PPE. Having this program is important, as it protects both the company, and more importantly, YOU from being injured and unable to work.

I will not go into any details on the specific OSHA requirements on PPE, but for anyone interested, you can find this info at www.osha.gov and type personal protective equipment into the search or look up OSHA standard 1910, primarily Subpart I.

I will leave you with this...It CAN happen to you and it could just be a matter of time until it does happen to you. Or maybe it will or has happened to someone close to you. Please be Safe out there. Feel free to send me any of your success stories or near

misses you would like to share. To that end, I have recently added some additional PPE to our product lineup. These items are all available and in stock currently.

EMAIL DARREN: dmcardle@gardnermarsh.com

EMAIL DARREN: dmcardle@gardnermarsh.com